| East industrial Zone, Anping, Hebei, China. – Anping County – China, Bohai Bay | +86-318-76632111 | |

| http://www.wiremeshpanel.com | ||

| Industry > METALS, minerals, scrap, virtual, holograms, APPS... Industry > OTHERS | ||

Expanded metal is a versatile and economical product that can meet various demands in different situations. The sheet, plate or coil be cut or slit and stretched into numbers of regular opening diamonds on the surface is called expanded metal.

Compared with its alternatives, expanded metal is more rigid and won't ravel if part is cut off because it is slit rather than perforated. And it is more cost-effective on account of its special expanding technic which causes none material loss in the manufacturing process. According to its different materials and wide ranges of specifications, expanded metal is used in different places. It is an ideal product used as fencing guard, partition, stair tread and catwalk grating. Therefore we provide a wide range of expanded products, as following:

By styles:

After slit and stretched, the sheet rises and falls regularly, which we called standard expanded metal (raised or regular expanded metal). After passing through the rolling mill the flattened expanded metal is finished.

Part of standard expanded metal being put on a blue background

EM-02: standard expanded metalPart of flattened expanded metal being put on a blue background.

EM-03: flattened expanded metal

By materials:

Many kinds of metals and alloys are suitable for expanded metal: carbon steel, stainless steel, aluminum, copper and alloy of nickel are very common materials. Then stainless expanded metal with different chemical elements can also be divided into such several types: Types 304, 304L, 316, 316L. The specifications vary with different types slightly.

A detailed drawing of white carbon steel expanded metal.

EM-04: carbon steel expanded metalA detailed drawing of stainless expanded metal.

EM-05: stainless expanded metal

A detailed drawing of white aluminum expanded metal.

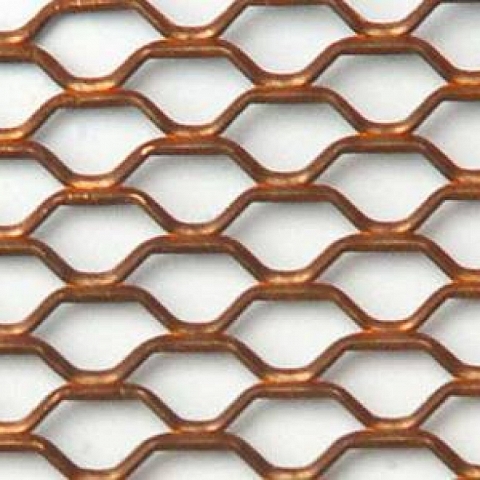

EM-06: aluminum expanded metalA detailed drawing of copper expanded metal.

EM-07: copper expanded metal

By finish types:

The usual finish methods include pre-galvanizing, hot-dip galvanizing, galfan-coating, anodizing, enameling, power coating, painting, PVC coating, etc. The most popular finish method for iron and steel products is galvanizing. Expanded metal can be sprayed or plated into any color. It is necessary for you to specify the wanted type of coating, thickness and color of finish.

A detailed drawing of white galvanized expanded metal.

EM-08: galvanized expanded metalA detailed drawing of green PVC coated expanded metal.

EM-09: green PVC coated expanded metal

A detailed drawing of black power coated expanded metal.

EM-10: black power coated expanded metalExpanded metal in green, blue, black, reseda, orange, red, gold.

EM-11: different hole shapes and colors of expanded metal.

By hole shapes:

The process of expanded metal being produced.

EM-12: expanded metal manufacturing process

The small animation shows that the top cutting die descends and simultaneously slits and cold forms an entire row of half diamonds; and then the top die ascends and moves one half diamond right as the base metal moves forward one strand width. With different shapes of cutting dies in machine, different shapes of openings are formed. diamond openings, hexagon openings, square openings, round openings and fan-shaped openings.

A detailed drawing of galvanized expanded metal with diamond openings.

EM-13: expanded metal with diamond openingsA detailed drawing of galvanized expanded metal with hexagon openings.

EM-14: expanded metal with hexagon openings

A detailed drawing of galvanized expanded metal with square openings.

EM-15: expanded metal with square openingsA detailed drawing of galvanized expanded metal with diamond and hexagon openings.

EM-16: expanded metal with diamond and hexagon openings

Edge configuration:

Condition of edge refers to two types: random (open) and bond (closed). Each sheet shall have closed diamond openings on all sides of the sheet unless ordered differently.

Expanded metal with random shearing edges and bond shearing edges.

EM-17: Two end random shearing edges and two end bond shearing edges.

Manufacturing tolerances:

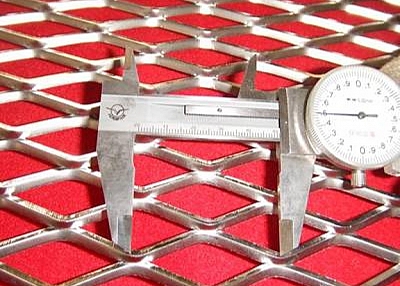

A ruler is measuring the LWD of a standard expanded metal sheet upon a red background.

EM-18: LWD will not vary from the nominal dimension more than 1/4-in. per foot (2 mm per 100 mm) of dimension.Wire diameter and thickness examination of expanded metal sheet by rulers.

EM-19: The thickness of flattened expanded metal shall not be less than 80 % of the nominal thickness of the corresponding raised expanded metal thickness.

Features:

Versatility: Expanded metal can be used to solve the many problems.

The flow of air and light: With different numbers and shapes of opening, the air and light can pass through easily according to your demands.

Variety opening shapes: Cut by different cutting dies, various openings would be offered.

Corrosion resistance: The product after Galfan coating is particularly corrosion resistant.

Strength and formability: The sheet will not unravel for its unique technic.

Durability: The combination of material and craft of expanded metal makes the panel more durable.

Economization: The product is slit and stretched, which causes no material loss.

Application:

Security fencing:

Installed around the perimeter of farm, garden, basketball court and other residential and industrial buildings to create a safer enclosure.

The product is favorable as security fencing in the highways.

Expanded metal could also used as handrail guard to protect people from danger.

To protect certain machines and animals, expanded metal fencing cage is an excellent choice.

Walkway Grating – platform and stair treads

Standard expanded metal provide safer surface for workers to walk and objects to support. What's more, it is easily to remove and install.

Ornaments:

Exterior and interior building used panels made of expanded metal bring users metallic texture. Normally, building facade, ceiling and partition wall employ expanded metal as decorations.

Expanded metal is perfect to pair with outdoor bench or picnic table.

Lampshade, by making light to reflect diffusely, diffuses or spreads out or scatters light in some manner, to give soft light.

Video, especially outdoor speaker, is extremely fragile. Therefore expanded metal made speaker cover help a lot.

Expanded steel trash basket with colorful appearance could be used in office, outside, etc.

As air and fluid filter, the expanded metal filter is able to give you what you want precisely.

Other applications:

As concrete reinforcement, the expanded metal make modern construction a possible.

As shelving to support goods.

As grill to roast delicious meat.

Trailer flooring.

Chimney caps.

Vents.

Screening.

Car grilles.

Speaker grilles.

Terminology:

For your convenience, certain knowledge of expanded metal specification is necessary. Its worth mentioning, SWD always given before LWD when ordering.

The picture indicates the certain position or of SWD, LWD, SWO, LWO, bond, etc.

EM-20:

SWD = short way of design

LWD = long way of design

SWO = short way of opening

LWO = long way of opening

bond = knuckle

This picture shows if LW parallels LWD of panel, it is standard flow expanded metal, if not, it is reverse flow type.

EM-21: Standard flow expanded metal means LW parallels LWD of panel, reverse flow expanded metal means SW parallels LWD of panel.

NOTE: Span of expanded metal grating always parallels LWD.

Table 1: Nominal weights and dimensions for standard-carbon steel expanded metal

Style Minimum thickness

(Inches)A Nominal weight in

Lbs. per 100 Sq. Ft.B Design Size

(Inches)C Opening size

(Inches) Strand size

(Inches) Overall thickness

(Inches) No. Of diamonds

Per Ft. Open area (%)

SWD LWD SWO LWO Width Thickness SWD LWD

1?4"-#20 .032 85 .250 1.00 .157 .718 .072 .036 .146 48 12 42

1?4"-#18 .042 113 .250 1.00 .146 .718 .072 .048 .151 48 12 42

1?2"-#20 .032 42 .500 1.20 .407 .938 .072 .036 .146 24 10 71

1?2"-#18 .042 69 .500 1.20 .382 .938 .088 .048 .180 24 10 65

1?2"-#16 .053 85 .500 1.20 .372 .938 .087 .060 .183 24 10 65

1?2"-#13 .083 141 .500 1.20 .337 .938 .096 .090 .212 24 10 62

3/4"-#16 .053 54 .923 2.00 .783 1.750 .101 .060 .208 13 6 78

3?4"-#13 .083 77 .923 2.00 .760 1.688 .096 .090 .212 13 6 79

3?4"-#10 .083 117 .923 2.00 .718 1.625 .144 .092 .300 13 6 69

3?4"-# 9 .127 178 .923 2.00 .675 1.562 .150 .134 .329 13 6 67

1"-#16 .053 43 1.00 2.40 .872 2.062 .087 .060 .183 12 5 83

1 1?2"-#18 .042 20 1.33 3.00 1.229 2.625 .068 .048 .144 9 4 90

1 1?2"-#16 .053 40 1.33 3.00 1.184 2.625 .108 .060 .221 9 4 84

1 1?2"-#13 .083 58 1.33 3.00 1.160 2.500 .105 .090 .228 9 4 84

1 1?2"-#10 .083 76 1.33 3.00 1.132 2.500 .138 .090 .288 9 4 79

1 1?2"-# 9 .127 119 1.33 3.00 1.087 2.375 .144 .134 .318 9 4 78

1 1?2"-# 6 .184 247 1.33 3.00 .979 2.313 .203 .198 452 9 4 69

2"-#10 .083 65 1.85 4.00 1.630 3.438 .164 .090 .335 6.5 3 82

2"-# 9 .127 88 1.85 4.00 1.603 3.375 .149 .134 .327 6.5 3 84

A The minimum thickness is absolute, not subject to minus variation.

B A variation in weight per square ft. of ±10% is permissible, based on the weight of any sheet or bundle.

C A tolerance of ±10 % is permitted in dimensions, center to center.

Table 2: Nominal weights and dimensions for flattened-carbon steel expanded metal

Style Minimum thickness

(Inches)A Nominal weight in

Lbs. per 100 Sq. Ft.B Design Size

(Inches)C Opening size

(Inches) Strand size

(Inches) Overall thickness

(Inches) No. Of diamonds

Per Ft. Open area (%)

SWD LWD SWO LWO Width Thickness SWD LWD

1?4"-#20 .026 74 .250 1.05 .092 .715 .079 .029 .029 48 11.6 37

1?4"-#18 .034 100 .250 1.05 .090 .715 .080 .038 .038 48 11.6 36

1?2"-#20 .026 37 .500 1.26 .342 1.000 .079 029 .029 24 9.5 68

1?2"-#18 .034 61 .500 1.26 .306 1.000 .097 .038 .038 24 9.6 61

1?2"-#16 .043 77 .500 1.26 .304 1.000 .098 .048 .048 24 9.5 61

1?2"-#13 .066 126 .500 1.26 .286 1.000 .107 .072 .072 24 9.5 57

3/4"-#16 .043 47 .923 2.10 .701 1.750 .111 .048 .048 13 5.7 76

3?4"-#14 .054 56 .923 2.10 .713 1.760 .105 .060 .060 13 5.7 77

3?4"-#13 .066 67 .923 2.10 .711 1.781 .106 .072 .072 13 5.7 77

3?4"-#10 .066 102 .923 2.10 .603 1.755 .160 .072 .072 13 5.7 65

3?4"-#9 .101 157 .923 2.10 .593 1.688 .165 .108 .108 13 5.7 64

1"-#16 .043 38 1.000 2.52 .804 2.250 .098 .048 .048 12 4.684 80

1 1?2"-#16 .043 35 1.330 3.15 1.092 2.750 .119 .048 .048 9 3.75 82

1 1?2"-#14 .054 43 1.330 3.15 1.098 2.750 .116 .060 .060 9 3.75 83

1 1?2"-#13 .066 51 1.330 3.15 1.098 2.750 .116 .072 .072 9 3.76 83

1 1?2"-# 9 .101 105 1.330 3.15 1.014 2.563 .158 .108 .108 9 3.75 76

A The minimum thickness is absolute, not subject to minus variation.

B A variation in weight per square ft. of ±10?% is permissible, based on the weight of any sheet or bundle.

C A tolerance of ±10?% is permitted in dimensions, center to center.

Item No.:

Item No. Is especially vital for the sake of ordering. For example:

Item No. : 1/2" #18F 4' SWD × 8' LWD

1/2" = short way of design (SWD)

#18 = 18 gauge

F = flattened

4' SW × 8' LW = size of sheet width × length

NOTE: F represents flattened, R represents raised.

Customization:

Standard specifications can be found in every specific product pages. And as an experienced manufacturer, special expanded metal with different materials, opening shapes and sizes, coatings, are available for clients' various demands.

Accessories:

The expanded metal is usually used as fencing guards, walkways, stair treads and decorates, and the requisite accessories for clients' demands, such as posts, rails, tension bars, tie wires clips for fencing, is all fitted as you can see in every specific product pages, but extra-chargeable.

Installation method:

The installation method for expanded metal is the same as any other metal sheet product for building.

Conventional fastenings.

Traditional welding.

Packaging and transportation:

To protect the goods, expanded metal is packed in sheet or roll into carton, crate or pallet and so on. International transportation procedures vary with the type of goods, delivery time and destination, but to meet your requirement our service specialists are always available for your request.

Discount: Discount varies with the type and quantity.

Ordering procedures: To improve users experience, please indicate the following data: material type, flattened or standard, wire diameter, hole shape, SWD, LWD, SWO, LWO, LW, SW, strand thickness (gauge), strand width, finish type, the thickness of coating, edge condition, weight per square ft. Accessories, packing and transportation method, etc. Therefore item No. is especially vital for ordering.

Anping Mengke Wire Mesh Manufacture Co., Limited

Activity: Anping Mengke Wire Mesh Manufacture Co., Limited

Anping Mengke Wire Mesh Manufacture Co., Limited is exactly who we are. Over the past 30 years, we have devoted ourselves in manufacturing wire mesh panel products. Located at East industrial Zone, Anping, Hebei, China, Anping Mengke Wire Mesh Manufacture Co., Limited deals with manufacturing, exporting and supplying quality wire mesh panel. As a professional manufacturer, we produce following welded wire and expanded metal products. Fence Welded double wire fence. 3D security welded wire fence. 358 anti climb fence. Palisade fencing. Paladin fencing. Architectural perimeter fencing. Snake fencing. Fencing for highway and railway. Expanded metal bannister guard. Expanded metal walkway grating Platform. Stair treads and ladder rungs. Cages Animal enclosure. Cage for animals and equipment. Ornaments Welded wire lath. Building exterior screening. Ceilings, windows, indoor partition walls (upholstery). Shelving and racks containers. BBQ grills. Table (indoors and outdoors). Trash basket. Lampshade. Chimney caps, vents. Our products are exported to Japan, Singapore, Australia, the United Kingdom, the United States, and other European countries. No matter who you are, distributor, contractor or downstream user, Mengke will always be your best partner. For Distributor Ensure products supplied in time. Quality guaranteed. 3-year free exchange Warranty. For Contractor Accessories well equipped. Installation guidance provided. Specialists for on-site teaching. For Downstream User Products' exterior packaging design from professional designers. Reasonable discount for long-term partners. Six steps for our products to go through. several rolls of galvanized wire is lying on earth. Stabilized material suppliersrightwelded wire fence panel is producing from a machine. Modern manufacturing equipment and skilled workersrightA box of fence examination machine is lying here. Rigorous and random quality inspectionbottom Palisade fence gone through a packaging process. Professional exterior packaging designersleftpallets with panels inside warehouse. Appropriate environment for production storageleftA ruler is examining the wire diameter. Secondary check-up before delivery to demand clients' requirements